HOME

ABOUT MR MOULDINPLA

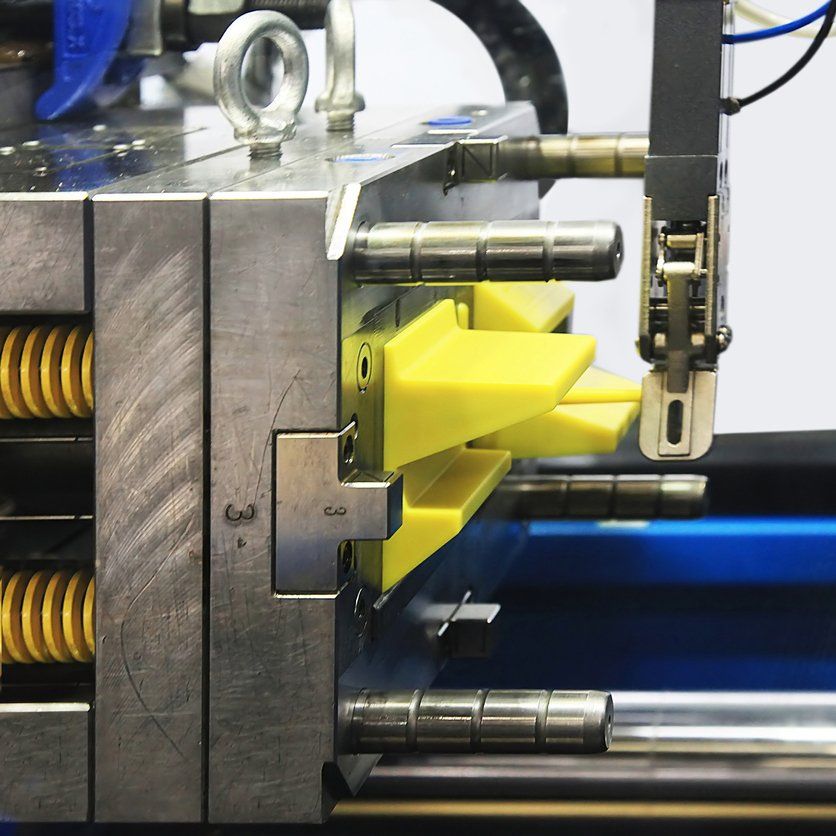

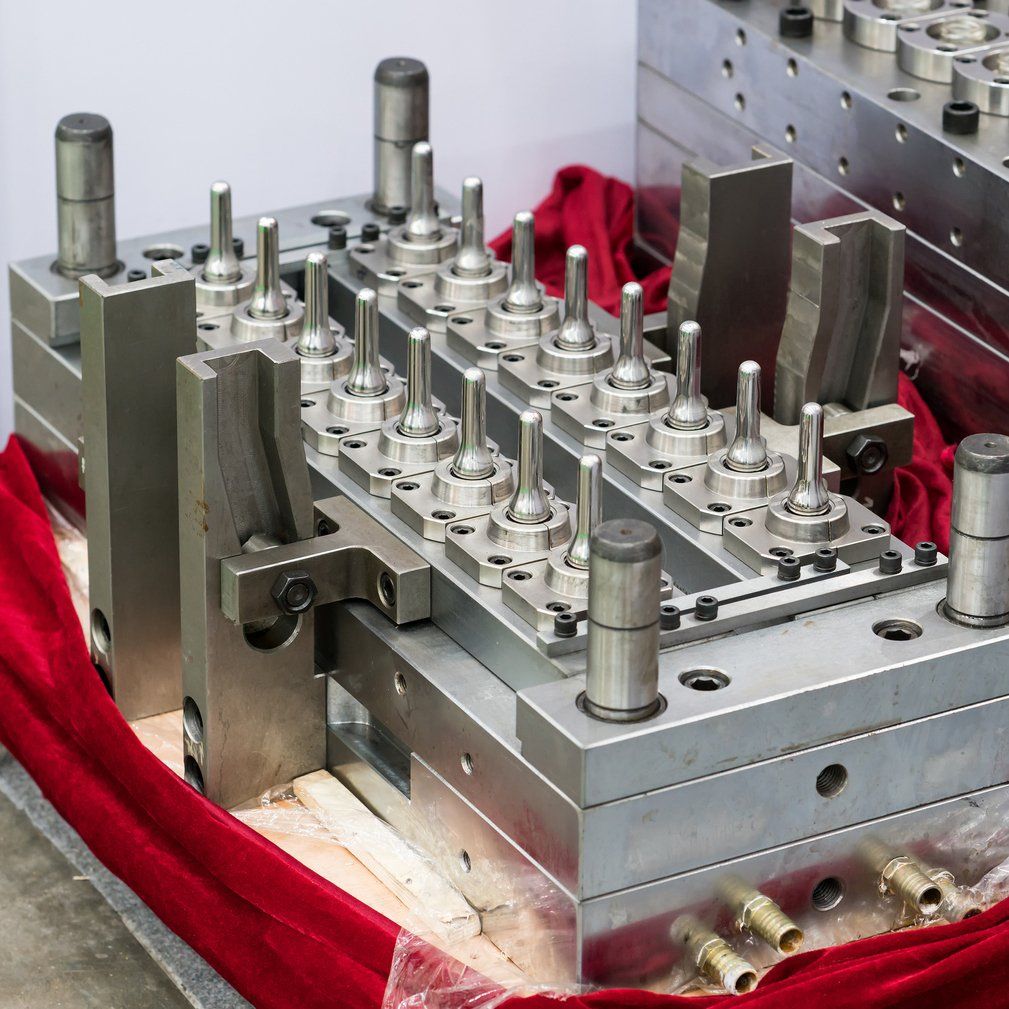

MR Mouldinpla specialises in maintenance (preventive) and repair (curative) of moulds and hot runners and changes (modificative) to moulds. On new moulds, I run a final check before they are taken into production. These could be anything from small moulds for medical devices to moulds for automotive components weighing as much as 42 tons. I have experience with a wide range of mould types, such as 96-cavity, single- and double-layer hot runner systems.

MR MOULDINPLA IS A SISE PARTNER

PROJECT SUPPORT

Having new moulds built or adapted by others is an intensive process that requires expertise.

TROUBLESHOOTING

Having help to hand fast when problems occur ensures continuity in your production processes.

TRAINING

The training I provide covers aspects such as material properties, process flows and how moulds work.

ABOUT MARIO RODRIGUES

I have been working in injection moulding since 1993. My first 11 years in the industry were spent in Marinha Grande, Portugal, where I was born. I came to the Netherlands in 2004, when a major manufacturer of plastic semi-end products for the automotive industry here invited me to input my expertise in injection moulding to strengthen their production process. My multilingualism often comes in handy in my work. I speak fluent English, Dutch and Portuguese and have a good working knowledge of Spanish and French.

I am trained in areas such as mould making, supervising projects involving the use of moulds and troubleshooting in the injection moulding process. I have worked as a trial injection moulding operator, process engineer and toolmaker in the automotive, packaging, electronics, medical and consumer goods sectors, where I gained experience in a wide range of injection moulding machines and techniques.

Now I am putting my knowledge and experience to good use in my own business, tapping into an extensive network of toolmakers, manufacturers and suppliers of hot runners and moulds as and when necessary.

If there is anything I can do for you, please don’t hesitate to contact me.

Mario Rodrigues

I am trained in areas such as mould making, supervising projects involving the use of moulds and troubleshooting in the injection moulding process. I have worked as a trial injection moulding operator, process engineer and toolmaker in the automotive, packaging, electronics, medical and consumer goods sectors, where I gained experience in a wide range of injection moulding machines and techniques.

Now I am putting my knowledge and experience to good use in my own business, tapping into an extensive network of toolmakers, manufacturers and suppliers of hot runners and moulds as and when necessary.

If there is anything I can do for you, please don’t hesitate to contact me.

Mario Rodrigues

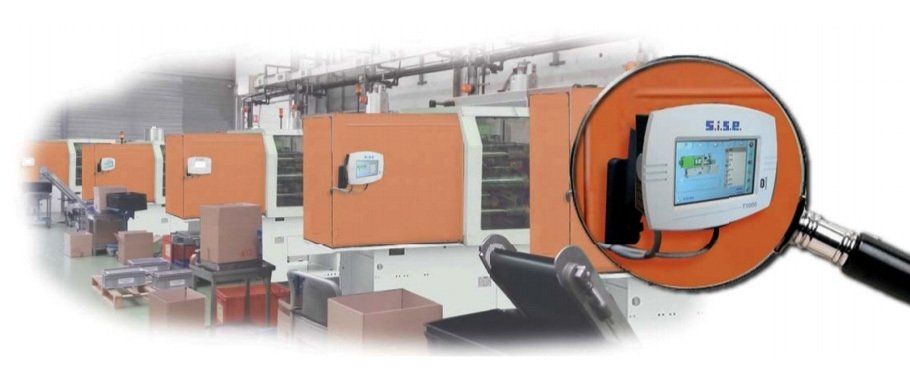

MR MOULDINPLA IS A SISE PARTNER

SISE designs and manufactures innovative equipment for the composites and plastics moulding industries. The quality and safety of moulds and finished products are monitored with comprehensive management of production and process data. Their range of products and services includes:

- Hot runner temperature controllers

- Sequential (cascade) injection controllers

- Water and oil temperature control

- Production and process support

- Production monitoring system (M.E.S. Cyclades)

SISE first approached MR Mouldinpla in early 2020. The company was looking for an industry expert in the Netherlands. After several phone and e-mail conversations, I visited SISE in August 2020. I then spent a few days at the company in October 2020 to familiarise myself with their products and working methods. We signed a cooperation agreement shortly afterwards.

For more information on SISE, visit:

MR Mouldinpla B.V.

Mario Rodrigues

Beekseweg 21F, 7031 AT Wehl, The Netherlands